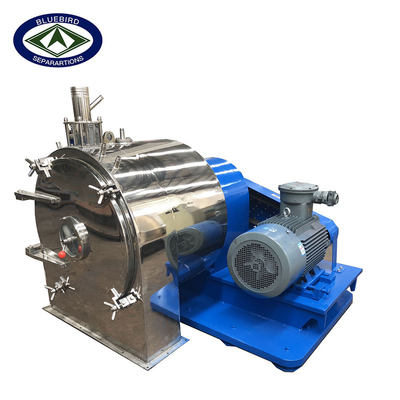

Blovebird horizontal screen scroll centrifuge has the advantages of large production capacity, good solid phase dehydration, low energy consumption and light weight.

Widely used in chemical, food, pharmaceutical and mining industries, and is suitable for the separation of solid-phase suspensions containing coarse crystals and short fibers.

Especially suitable for separating suspension of easy dehydration and high concentration.